How to correctly select the material for Neutral Grounding Resistors (NGR)?

Writer: admin Time:2026-01-09 17:18:27 Browse:65℃

I. How to correctly select the material for Neutral Grounding Resistors

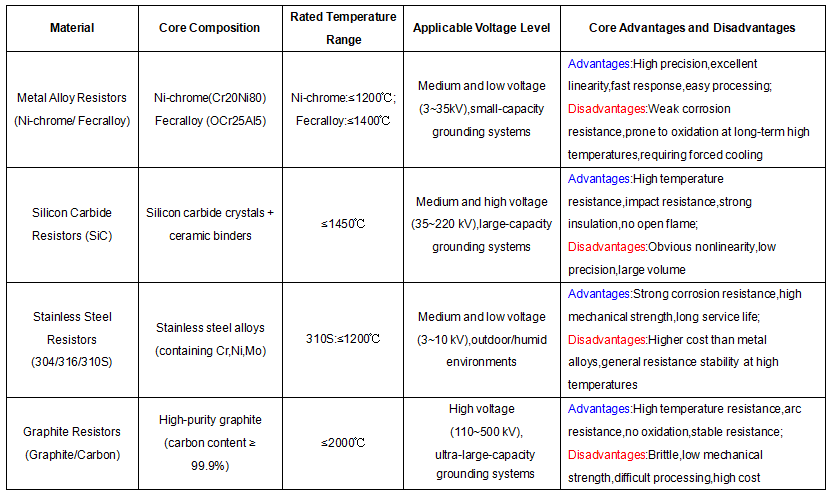

Neutral grounding resistors are core devices in power systems used to limit ground fault currents and suppress arc grounding overvoltages. Their material directly determines the resistor’s rated capacity, thermal stability, service life, and operation and maintenance costs. Currently, mainstream materials are divided into four categories: metal alloy resistors, silicon carbide resistors, stainless steel resistors, and graphite resistors. In special scenarios, zinc oxide nonlinear resistors and other auxiliary types are used. This article elaborates on material characteristics, advantages and disadvantages, selection methods, and engineering cases.

II. In-depth Analysis of Advantages and Disadvantages of Each Material

1. Metal Alloy Resistors (Nichrome/Fecralloy)

Advantages:

① Resistance precision can reach ±0.5% with excellent linearity, suitable for scenarios requiring precise current limiting;

② Fast response speed (millisecond level), capable of quickly suppressing short-circuit currents;

③ Can be processed into strip, filament, and sheet shapes with flexible structure, adapting to small-volume equipment.

Disadvantages:

① Prone to oxidation at high temperatures, requiring nitrogen protection or sealed structure for long-term operation;

② Poor corrosion resistance, not suitable for outdoor, coastal, and other humid and saline environments;

③ Fecralloy has weak vibration resistance and needs reinforced installation.

2. Silicon Carbide Resistors (SiC)

Advantages:

① High temperature resistance without open flame, insulated shell design, excellent explosion-proof performance, suitable for outdoor high-voltage scenarios;

② Strong ability to withstand impact current, capable of bearing instantaneous impact of short-circuit current (10~20 times the rated current);

③ Good chemical stability, acid and alkali corrosion resistance, no need for additional anti-corrosion measures.

Disadvantages:

① Negative temperature coefficient leads to large resistance fluctuation with temperature, resulting in low current limiting precision;

② Large volume (3~5 times larger than metal alloy resistors of the same capacity), requiring high installation space;

③ High resistance at low temperatures may generate instantaneous overvoltage during startup.

3. Stainless Steel Resistors (304/316/310S)

Advantages:

① 316/310S materials are resistant to chloride ion corrosion, suitable for harsh environments such as coastal areas and chemical plants;

② High mechanical strength, vibration and impact resistance, can be directly installed outdoors;

③ Long service life (about 15~20 years) with low operation and maintenance costs.

Disadvantages:

① Low resistance precision (±5%~±10%), not suitable for high-precision current limiting;

② 304 material is prone to carbide precipitation at high temperatures, affecting resistance stability;

III. Systematic Method for Material Selection (6-step Decision Model)

Clarify System Parameters: Determine the system voltage level (e.g., 10 kV/35 kV/110 kV), ground fault current (e.g., 1000 A/3000 A), continuous operation time (e.g., 10 s/60 s), and environmental conditions (indoor/outdoor, humidity, salt spray, temperature range).

Prioritize Matching Core Indicators

High-precision current limiting (e.g., small-capacity medium and low voltage systems): Prioritize metal alloy resistors;

High-voltage large-capacity + impact resistance (e.g., substation main transformer neutral point): Prioritize silicon carbide resistors;

Harsh environments (coastal/chemical industry/outdoor): Prioritize stainless steel resistors (316/310S);

Ultra-large-capacity + long-term operation (e.g., UHV systems): Prioritize graphite resistors.

Verify Thermal Stability: Calculate the thermal power of the resistor (P=I²R) according to the short-circuit current and continuous time to ensure that the rated temperature and power density of the material meet the requirements and avoid overheating and burning.

Evaluate Economy: Comprehensively consider procurement cost, installation cost, and operation and maintenance cost (e.g., metal alloy resistors need regular replacement, while graphite resistors are almost maintenance-free) to select the scheme with the optimal whole-life cycle cost.

Compliance and Standards: Comply with standards such as GB/T 14285, DL/T 620, and IEC 62271 to ensure that the insulation performance, short-circuit withstand capacity, and protection level (IP54/IP65) of the resistor meet the standards.

Special Scenario Supplement: For suppressing arc grounding overvoltage, zinc oxide nonlinear resistors can be used in combination; for rapid current interruption, linkage with circuit breakers is feasible.

IV. Engineering Case Examples

Case 1: 10 kV Distribution Network Neutral Grounding Resistor (Medium and Low Voltage, High-precision Scenario)

System Parameters: 10 kV distribution network, ground fault current 1000 A, continuous operation time 10 s, indoor installation, ambient temperature -10℃~40℃.

Material Selection: Nichrome Alloy Resistor (Cr20Ni80)

Selection Basis: High precision (±1%), excellent linearity, capable of precisely limiting short-circuit current; no corrosion in indoor environment, no need for additional anti-corrosion measures; high power density, small volume, saving installation space.

Configuration: Resistance value 10 Ω, rated power 10 MW, air-cooled heat dissipation, protection level IP54.

Case 2: 35 kV Substation Main Transformer Neutral Grounding Resistor (Medium and High Voltage, Impact-resistant Scenario)

System Parameters: 35 kV substation, ground fault current 3000 A, continuous operation time 30 s, outdoor installation, coastal area (high salt spray concentration).

Material Selection: Silicon Carbide Resistor (SiC)

Selection Basis: Strong impact current withstand capacity, capable of bearing 3000 A short-circuit impact; high temperature resistance (1400℃), no open flame outdoors, safe explosion-proof; salt spray corrosion resistance, no need for anti-corrosion treatment; negative temperature coefficient can alleviate instantaneous overvoltage.

Configuration: Resistance value 12 Ω, rated power 27 MW, natural heat dissipation, protection level IP65, shell reinforced with stainless steel material.

V. Supplementary Selection Suggestions

Material Hybrid Scheme: In high-voltage systems, a combination of "silicon carbide resistors + metal alloy resistors" can be adopted to balance impact resistance and high precision;

Temperature Compensation Measures: For silicon carbide and graphite resistors with negative temperature coefficients, small-capacity positive temperature coefficient resistors can be connected in series to improve resistance stability;

Operation and Maintenance Priority: Metal alloy resistors need regular inspection of oxidation, stainless steel resistors need regular cleaning of surface salt spray, and graphite resistors need sealed dust prevention.

CATEGORIES

- Neutral Grounding Resistor for Transformer

- Generator Neutral Grounding Resistor

- Low Voltage Neutral Grounding Resistor

- Neutral Grounding Arc Suppression Coils (Peterson Coil)

- Neutral Point Gap Grounding Protection Device

- Nitrogen Injection Fire Protection System for Transformer (NIFPS)

- Transformer Air-Cooled Control Equipment

- Nonlinear Neutral Grounding Equipment

LATEST NEWS

- Why Does the Neutral Point of a Large Generator Need to be Reliably Grounded?

- Transformer Neutral Grounding Methods and Applications for High-, Medium-, and Low-Voltage Systems

- How to Accurately Calculate the Neutral Grounding Resistance Value of a Transformer

- Global Top 8 Neutral Grounding Resistor (NGR)Manufacturers

- How to size a Neutral Grounding Resistor (NGR) for a 13.8 kV system with a 10 A limit?

CONTACT US

WhatsApp: +86-18631228466

Tel: +86-312-5959618

Email: info@orionresistors.com

Add: No. 79, Fuchang Road, Zhongguancun Entrepreneurship Base, Baoding City,China