How to Select Right Neutral Grounding Resistor (NGRs)Manufacture?

Writer: admin Time:2025-12-27 09:59:39 Browse:62℃

Neutral Grounding Resistor (NGR) Selection Guide for Power Systems

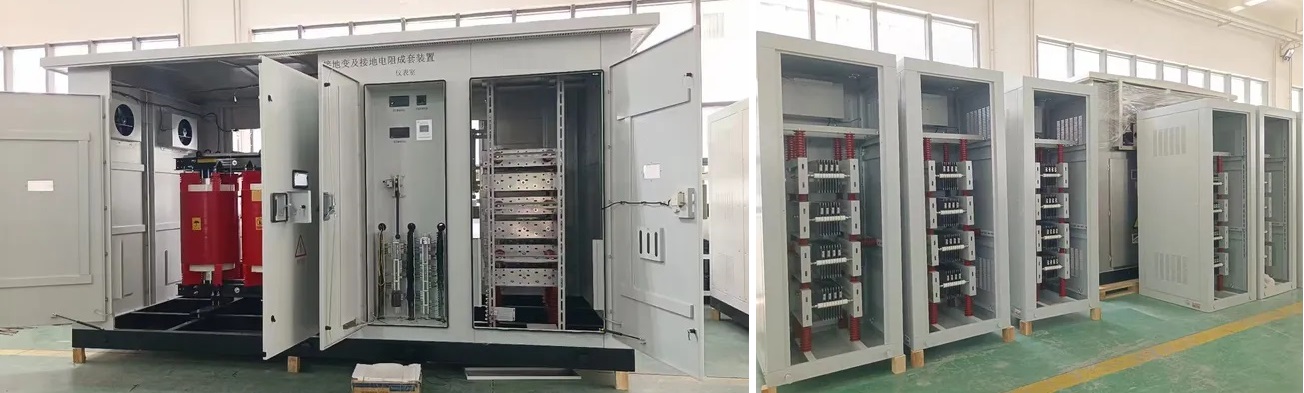

In power systems, the Neutral Grounding Resistor (NGR) is often referred to as the "safety valve" of the electrical grid. It connects the neutral point of a transformer or generator to the ground, with the core mission of limiting fault current during a single-phase ground fault by introducing a precisely calculated resistor into the system.Given the wide range of equipment prices, from tens of thousands to hundreds of thousands, and the many brands available, how do you select a manufacturer with true core competitive strength?

1. Technical Depth: Understanding Principles and Solution Design Capabilities

A top-tier manufacturer must be an excellent solution provider, not just an assembly workshop.

Precision of Parameter Calculation: Selecting an NGR is not about purchasing off-the-shelf components, but rather matching the resistor value to the power grid parameters. Manufacturers need to calculate based on the system's capacitive current and determine the correct resistor value (R) to suppress resonant overvoltages. Can the manufacturer provide a detailed simulation report to show the depth of their R&D capabilities?

Targeted Application Scenarios:

a.Generator Neutral Point (GNGR): Focused on protecting the stator windings. Since the allowed ground fault current in generators is extremely low, grounding transformers (NGT) are often used. Does the manufacturer understand the transient process inside the generator during a single-phase fault?

b.Industrial/Mining/Data Centers: These scenarios require continuous power supply, and may need either low-resistance grounding (LRG) for fast fault clearance or high-resistance grounding (HRG) for fault-tolerant operation. Does the manufacturer have experience handling non-linear load interference?

2. Core Components: Resistor Element Material and Connection Process

The resistor element is the "heart" of the NGR, and its quality directly determines the equipment's survivability under extreme conditions.

Material Selection: The industry mainly uses stainless steel (e.g., Cr20Ni80, Cr25Ni20) or specialized aluminum-chromium alloys. A quality manufacturer should provide spectral analysis reports for the materials. The key metric is the resistance temperature coefficient (TCR), which should show minimal fluctuation under high temperatures (e.g., 200°C), ensuring the current-limiting effect is not lost within seconds during a fault.

Manufacturing Process (Key Points):

Welding vs. Bolting: Full argon-arc welding is strongly recommended. The NGR will experience intense thermal expansion and mechanical vibration during operation, making bolted connections prone to loosening and causing contact resistance and potential fires. Examine whether the manufacturer's welds are smooth and free of voids.

Heat Dissipation Structure: Inspect the arrangement of resistor plates. A top-tier manufacturer will use a tiered ventilation design, utilizing the "chimney effect" for natural convection cooling. For large current (>100A) equipment, check if the insulation support structure is reinforced to withstand electromagnetic shock.

3. Manufacturing Process: Cabinet Design and Insulation Standards

Cabinet Material and Protection: Outdoor NGRs should use stainless steel (e.g., SS304) or cold-rolled steel with a powder-coating process. The protection level should be customized based on the environment, such as C5 corrosion protection for coastal areas or sandproof filters for desert regions.

Insulation Performance: Although NGRs typically operate at low voltages, they must withstand full-line voltage during fault conditions. The manufacturer should select high-quality insulators and ensure that electrical clearance and creepage distances strictly comply with IEC 60071 insulation coordination standards.

4. Stringent Quality Control Standards: Data-Driven Decisions

A qualified NGR must pass a series of type tests. When selecting a manufacturer, always review their third-party type test reports from the past three years:

Temperature Rise Test: Validates whether the maximum temperature rise of the resistor element meets the standards under rated current and time (e.g., 100A for 1 minute).

Power Frequency and Lightning Impulse Tests: Verifies the overall insulation level of the cabinet.

Factory Inspection: Each unit should undergo resistance value measurement (error within ±5%) and power frequency withstand voltage tests (typically 1.5 times the rated voltage).

5. Digitalization Trend: Intelligent Controller Integration

In the era of smart grids, a simple "iron box" is no longer sufficient. Leading manufacturers will offer intelligent monitoring units:

Real-Time Data: Monitors neutral point current, resistor plate temperature, and environmental temperature/humidity.

Fault Logging: Automatically records the time, duration, and maximum current of the grounding fault, which is crucial for fault tracing.

Communication Capabilities: Supports IEC 61850 or Modbus RTU for seamless integration with the substation automation system (SCADA).

6. Packaging and Logistics: The Overlooked Delivery Quality

Due to the fragile ceramic insulators and heavy metal components inside the NGR, improper logistics could lead to damage upon arrival.

Packaging: Quality manufacturers use reinforced export-grade wooden boxes with anti-shock bubble wrap and securing brackets inside.

Accompanying Documents: Must include the user manual, test reports, certificates of conformity, and detailed wiring diagrams (including secondary circuits).

How to Make the Final Decision?

When evaluating manufacturers, I recommend a "three-step approach":

Check References: Focus on whether the manufacturer has operated for a long time in similar projects (e.g., wind farms).

Examine Reports: Thoroughly check the type test reports to ensure that the capacity and voltage levels cover the required specifications.

Inspect the Details: If possible, conduct a video or on-site visit to inspect their welding workshops and quality control labs.

Choosing a top-notch NGR manufacturer is not just about purchasing qualified equipment—it's about investing in long-term safety for the power grid.

CATEGORIES

- Neutral Grounding Resistor for Transformer

- Generator Neutral Grounding Resistor

- Low Voltage Neutral Grounding Resistor

- Neutral Grounding Arc Suppression Coils (Peterson Coil)

- Neutral Point Gap Grounding Protection Device

- Nitrogen Injection Fire Protection System for Transformer (NIFPS)

- Transformer Air-Cooled Control Equipment

- Nonlinear Neutral Grounding Equipment

LATEST NEWS

- Why Does the Neutral Point of a Large Generator Need to be Reliably Grounded?

- Transformer Neutral Grounding Methods and Applications for High-, Medium-, and Low-Voltage Systems

- How to Accurately Calculate the Neutral Grounding Resistance Value of a Transformer

- Global Top 8 Neutral Grounding Resistor (NGR)Manufacturers

- How to calculate the neutral grounding resistance for 3.3kV, 4.16kV, and 6.6kV systems?

CONTACT US

WhatsApp: +86-18631228466

Tel: +86-312-5959618

Email: info@orionresistors.com

Add: No. 79, Fuchang Road, Zhongguancun Entrepreneurship Base, Baoding City,China